You can make more things and save money by fixing problems in robotic welding stations.

- Companies made almost twice as many welds after they improved their systems.

- Robotic welding helps make more products, fills worker shortages, and gives steady, good results.

Think about how you work. Solving these problems can change your results a lot.

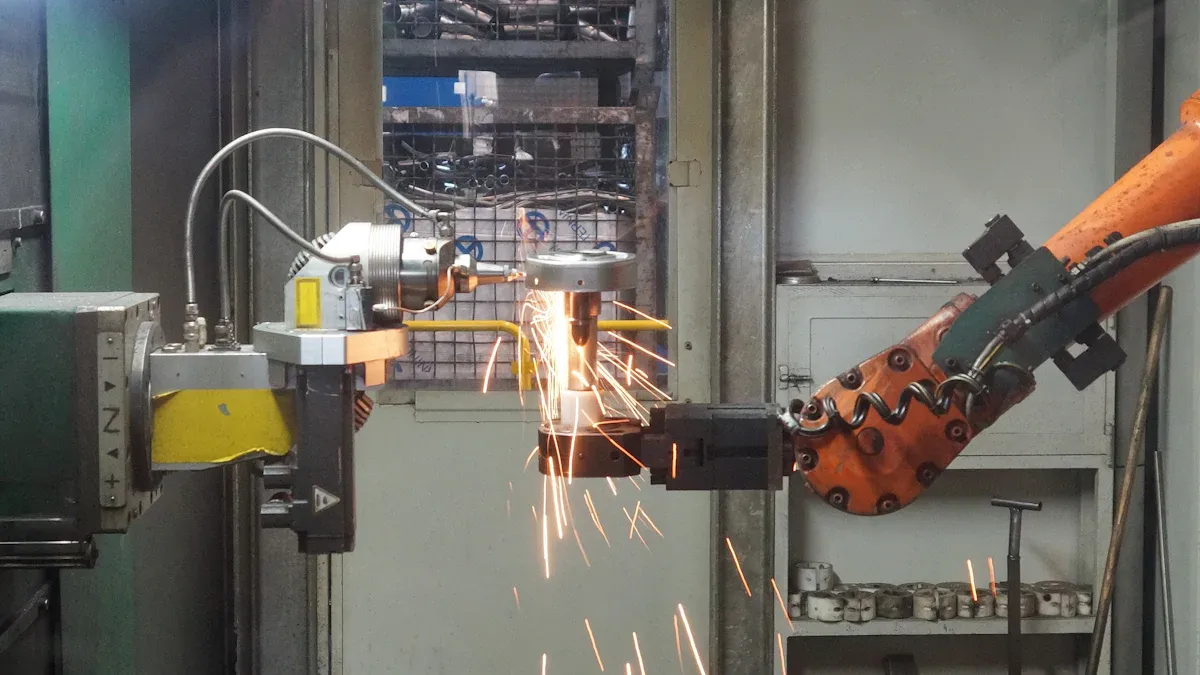

Robotic Welding Challenges

Equipment Reliability

Robotic welding stations can have many equipment problems. Things like burnback, broken cutter blades, and programming mistakes can stop work. The table below lists some common problems and what causes them:

| Common Issue | Cause |

|---|---|

| Burnback and premature contact tip wear | Gun liner not trimmed right, bad wire, tight drive rolls, wrong welding settings |

| Broken cutter blades | MIG gun nozzle not in the right spot or angled too much during cleaning |

| Loss of TCP | Consumables not put in right, worn clutch, programming mistakes |

| Damaged disc | Hard hits from crashes, so it needs to be replaced |

| Programming errors | Wrong path programming makes the robot hit tools or walls |

You can stop long delays by checking these things often and fixing problems fast.

Process Optimization

Process optimization helps you get the best from robotic welding. Problems can happen if part sizes change or if surfaces are dirty. Here are some common problems:

- Parts that are not the same size can mess up welding.

- Dirty surfaces make welds worse.

- If material quality changes, joints may not be good.

You can make more products if every part is checked and meets the right standards before welding.

Quality Control

Quality control helps keep welds good in robotic welding. Many things can cause bad welds, like wrong welding settings or bad joint design. For example, welding speed, arc voltage, and current all affect weld quality. Robotic welding usually makes fewer mistakes and better welds than people. You can find problems early by checking and doing maintenance often.

Workforce Skills

You need new skills to use robotic welding stations. Now, workers need to know programming and system management, not just welding by hand. Training programs like the Lincoln Electric ClassMate® Robotic Trainer and Automation Training help workers learn these new skills. Teaching your team new skills helps you get the best results from robotic welding.

Troubleshooting Robotic Welding

AI and Monitoring

You can make robotic welding stations work better with AI and real-time monitoring. AI watches welding settings and makes fast choices to help quality. Machine vision finds problems quicker than old ways. AI can guess when equipment might break, so you save time and money.

- AI checks welds faster and makes fewer mistakes.

- Predictive maintenance warns you about possible breakdowns.

- AI robots fix errors right away, so there is less waste and better quality.

- 3D vision systems help keep welds the same and boost productivity.

Real-time monitoring lets you change welding settings right away. You can stop problems and keep welds good. The table below explains how these tools help robotic welding stations:

| Capability | Description |

|---|---|

| Adaptive Parameter Control | Changes welding settings automatically using real-time feedback. |

| Joint Tracking | Fixes the robot’s path based on part position and joint shape. |

| Defect Prevention | Finds problems early and fixes them automatically. |

| Quality Prediction | AI guesses weld quality using real-time data. |

Automated inspection systems can find ten times more defects. These systems also help when there are not enough skilled workers.

Tip: Use AI and machine vision to keep robotic welding stations working well and catch problems early.

Maintenance Practices

Good maintenance keeps robotic welding stations running smoothly. Regular checks and cleaning stop breakdowns. You should look at the welding power source, torch, and wire feeder often. Back up your controller and software to keep your data safe.

- Clean the mechanical unit and control cabinet.

- Check and change grease in robot gearboxes.

- Change backup batteries often.

- Keep the control cabinet clean inside.

Follow the robot maker’s plan for maintenance. Some jobs can be done during breaks, but others need more time. Preventive maintenance helps your equipment last longer and saves money. If you skip maintenance, you may have surprise breakdowns and spend more.

- Scheduled maintenance protects your machines.

- Regular care stops failures and downtime.

- Consistent maintenance makes robotic welding systems last longer.

You can keep robotic welding stations working their best by following a maintenance plan.

Training and Upskilling

You need to train your team to use robotic welding stations well. Workers must learn new skills, like programming and system management. You can use different ways to teach your team:

| Training Method | Description |

|---|---|

| Vocational Training | Short programs that teach welding skills and basic robot use. |

| Associate Degrees | Two-year programs with welding, robot programming, and hands-on labs. |

| Certification Programs | Proves skills and knowledge, helps get better jobs; includes AWS Certified Robotic Arc Welding. |

| Mentorship | Experienced workers give advice and share best practices. |

Robotic welding makes work faster, safer, and more exact. Training helps your team keep up with new technology and meet industry needs. When you train your team, you get more products and better workflow. At D’Angelo Marine Exhaust, robots made workers happier and let welders do skilled jobs.

Note: Keep training and teaching new skills for the best robotic welding results.

Productivity Case Studies

You can learn from companies that fixed robotic welding problems and got better results. The table below shows how different ideas helped companies do more:

| Company | Strategy Implemented | Productivity Gain |

|---|---|---|

| Mach Machines | Used offline programming and better toolpaths | Got more work done and faster cycles |

| SSP | Used a robot to run a press line | Cut production costs by 35% |

| Walt Machine | Added three robot helpers to mills and lathes | Made 2,500% more parts per batch |

| Mach Machines | Changed welding cell layout and used offline programming | Cut programming time by 90%, did more work, and faster cycles |

You can see how fixing robotic welding problems helps. Companies work faster, spend less, and make more products. For example, Walt Machine made 2,500% more parts after adding robot helpers.

| Metric | Without Control | With Active Control | Difference |

|---|---|---|---|

| Weld Pool Width | 10.8 mm | 10.6 mm ± 0.4 mm | 0.2 mm |

| Position Deviation Compensated | 11 mm | N/A | N/A |

| Weld Length | 150 mm | N/A | N/A |

Active control helps you get welds that are more even and better quality.

Callout: Robotic welding stations with smart troubleshooting get faster, better, and cheaper results.

You can make more products by using automated nozzle cleaning, good cable management, and robotics training. Companies that spend money on new tools and teaching workers have fewer mistakes and spend less money.

Begin making your robotic welding station better now to help your business for a long time.

FAQ

What is the most common problem in robotic welding?

You often see equipment issues like worn tips or programming mistakes. Regular checks and quick fixes help you avoid long delays.

How can you improve weld quality in robotic welding?

You can use real-time monitoring and AI tools. These help you spot problems early and keep welds strong and even.

Do workers need special training for robotic welding?

Yes. You need to learn robot programming and system management. Training programs and mentorship help you build these new skills.