I think robotic welding is changing manufacturing in a big way. Robotic welding uses machines to do welding jobs fast and well. Companies pick robotic welding because it is faster, safer, and more exact. The market is getting bigger, as you can see below:

Robotic welding helps when there are not enough workers. It also makes the work better.

Robotic Welding Overview

What Is Robotic Welding

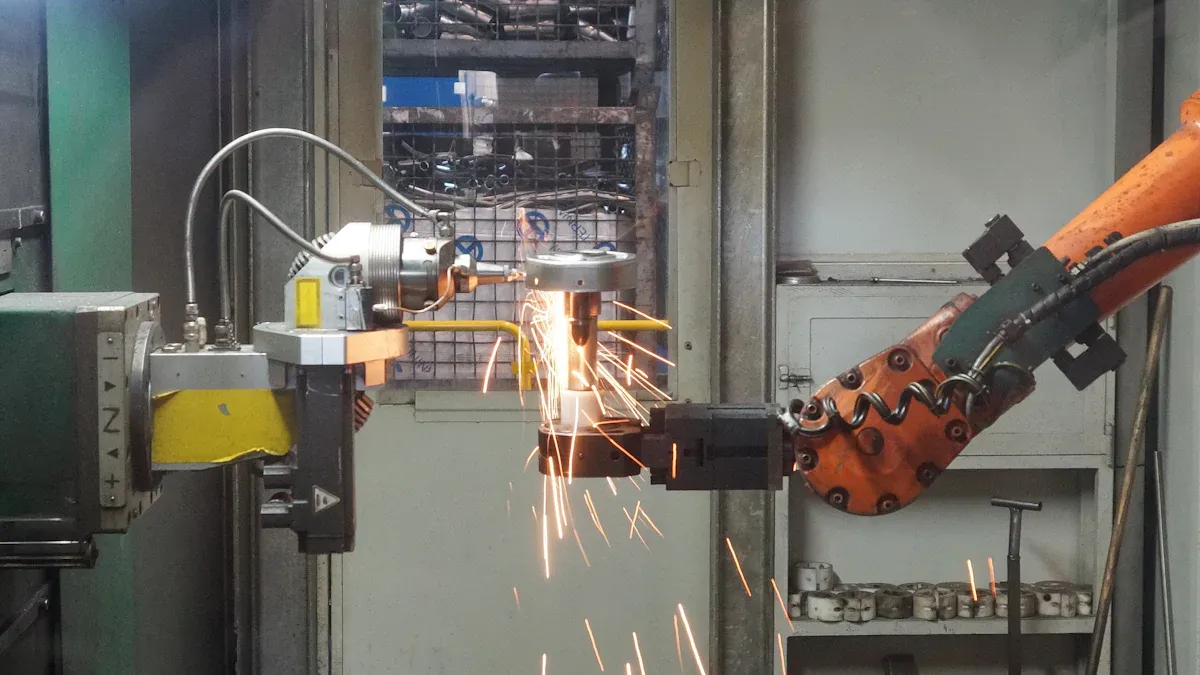

Robotic welding is a way to join metal parts using machines. These machines are programmed to do welding jobs over and over. They use robotic arms, controllers, and welding torches to work. You can find robotic welding in car factories, airplane making, and big metal shops.

Robotic welding systems have important parts:

- The robotic arm moves very carefully.

- The controller tells the robot what to do.

- The welding torch does the joining of metal.

- Power supplies give the energy needed.

- Sensors help the robot make quick changes.

All these parts work together to make strong welds every time. Robots can do the same job many times and reach tight spaces. This is helpful when making lots of products. There are different ways to do robotic welding, like arc welding, spot welding, and laser welding.

How It Works

The robotic welding process is smart and easy to follow. Here is how it usually goes:

- The metal part is put in a fixture so it does not move.

- The right welding program is picked or set up.

- The start button is pressed, and the robot begins welding.

- While the robot works, another part can be loaded.

- The robot finishes one weld and moves to the next.

- The finished part is taken out, and a new one is put in.

Welding robots use sensors and controls to make sure each weld is right. Sensors check if the part is in place, look at its size and shape, and follow the weld line. The controller keeps the welding programs and runs them. The teach pendant lets people make changes if needed.

Human and Robot Collaboration

Even though robots do most of the welding, people are still needed. People program the robots, set up jobs, and watch the work. They make sure everything goes well and safely. They also fix and take care of the machines.

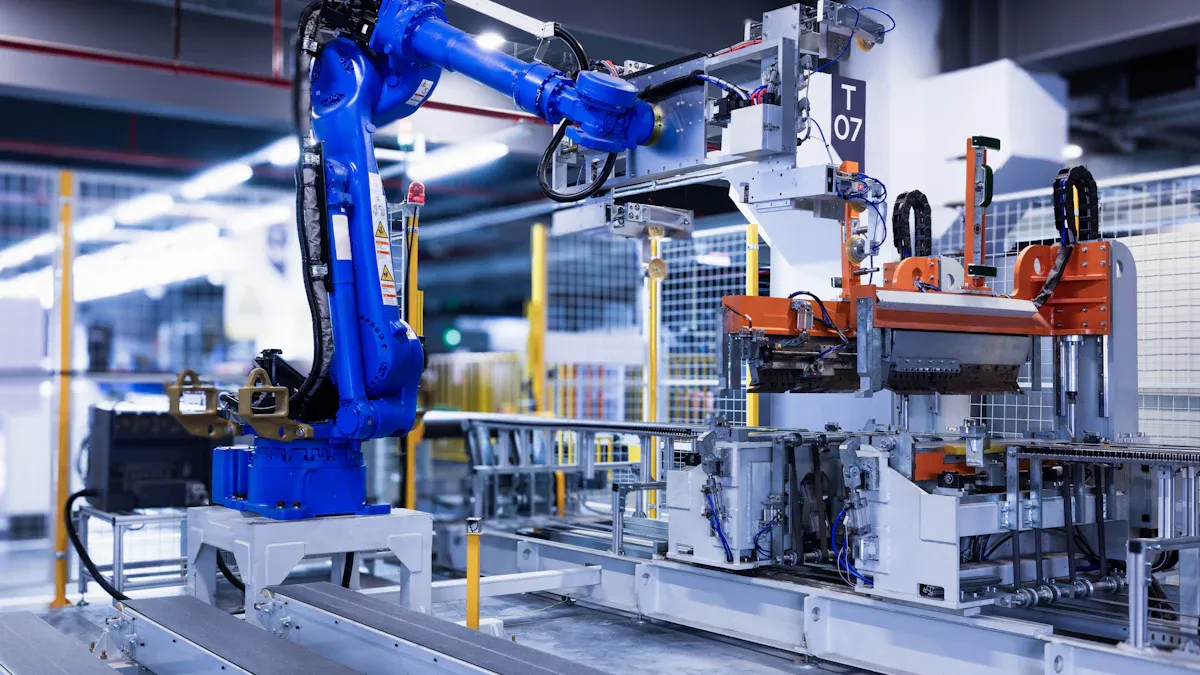

Cobots, or collaborative robots, have changed how people work with robots. Cobots are smaller, easy to use, and safe. People can work right next to them and share jobs. Cobots have safety features like soft joints and sensors. If someone gets too close, the cobot stops to keep them safe.

Here are some ways people work with welding robots and cobots:

- They program and set up the robots.

- They watch the welding and make changes if needed.

- They keep records of programs and repairs.

- They teach others how to use the robots.

- They make sure everyone follows safety rules.

Cobots let people do harder welding jobs while the robot does the easy ones. Working together makes the job safer and faster. People and robots help each other to make better products every day.

Robotic Welding Processes and Impact

Main Robotic Welding Processes

There are different types of robotic welding. Each type is good for certain jobs. I use a table to compare the main types. This helps me pick the best one for each job.

I use arc welding methods like MIG and TIG a lot. MIG is fast and works well on thick metal. TIG gives more control for thin or detailed work. Plasma arc welding lets me change the heat and speed. This helps with both thin and thick metals. Spot welding is great for car frames in big factories. Laser welding is very exact, so it is good for electronics and medical tools. These types help me pick the right process for every project.

Benefits

Robotic welding has many good points. The first thing I notice is how much faster jobs get done. Offline programming saves a lot of time. I spend less time setting up and more time welding. My work speed often doubles, and jobs finish quicker. Mistakes go down by half, so I save time and money.

Robotic welding gives high-quality welds every time. Robots do not get tired, so they work at the same speed all day. There are fewer mistakes and less waste. My products look better and need less fixing. I also save money on labor, which helps when there are not enough skilled welders. Some companies saw their work speed go up by 400% after using robots. This means they can take bigger jobs and earn more.

Robotic welding is also better for the environment. Robots use less energy and make less waste. Automated systems have better air cleaning, so the air is cleaner. There is less noise and fewer bad fumes, which makes the workspace safer.

Drawbacks

Robotic welding also has some problems. The biggest problem is the high starting cost. I need to buy the robot, safety gear, and pay for training. Setting up takes time and skill. I must learn to program and take care of the robots. Sometimes, hard jobs need advanced programming skills.

Regular care is another challenge. I have to clean, oil, and check the robots often. If something breaks, I need help fast to keep working. My shop needs enough space for the robots, so I might have to move other things.

Robotic welding is not as flexible for small or custom jobs. Programming and setup take time, so it works best for big batches. For short runs or special parts, manual welding is still better. Cobots help with flexibility, but they cannot do everything a skilled welder can do for one-time jobs.

Applications

Robotic welding is used in many factories today. The most common places are car, airplane, and building industries. In car factories, robots weld body panels, frames, and fuel tanks. In airplanes, robots weld wing parts and landing gear. Building companies use robots to weld steel beams and trusses for bridges and buildings.

| Sector | Common Robotic Welding Applications | Examples of Welded Parts | Benefits Highlighted |

|---|---|---|---|

| Automotive | Spot welding, arc welding, resistance welding | Vehicle body panels, chassis, fuel tanks | High precision, consistency, efficiency, reduced human error |

| Aerospace | Precision welding for structural assembly | Wing parts, landing gear components | Strong, durable structures, precise alignment |

| Construction | Welding large steel components for structural integrity | Bridges, buildings, support beams | Consistent welds, high repeatability, productivity |

I also see robots in motorcycle and gym equipment factories. Kawasaki Motors has used robotic welding for over 22 years. This shows how reliable these systems are. Gym equipment makers use robots for smoother welds and more work done. These real examples show how robots help make better products in many industries.

Manual vs. Robotic Welding

Manual and robotic welding are very different. Manual welding is more flexible. I can do custom, small, or tricky jobs fast. I can change what I am doing without reprogramming. Manual welding is best for repairs, test pieces, and odd shapes.

Robotic welding is best for big, repeat jobs. Robots weld much faster—up to 80 inches per minute. Manual welding is usually under 20 inches per minute. Cobots can go even faster, up to 90 inches per minute. Robots keep the same quality and speed all day. People get tired and make more mistakes after a while.

Robotic welding makes high-quality welds with fewer mistakes. Robots do not get tired, so they stay accurate. There is less waste and scrap. Manual welding, while flexible, can have more mistakes, especially during long shifts.

Training is different too. Robotic welding operators learn programming, fixing problems, and system care. Manual welders focus on welding skills and safety. Both need hands-on practice, but robotics adds more skills to learn.

I often ask companies like EVST for help with my robotic welding systems. They give support, training, and new technology. This makes it easier for me to get the most from my robots.

Robotic welding is changing how things are made today. These systems make work safer, better, and faster.

- They work all day and night without stopping. They help use less material and solve worker shortages.

- EVST helps more businesses use robotic welding.