6-axis robots provide exceptional flexibility and precision for challenging tasks. These 6-axis robots are widely used, accounting for about 70% of all industrial robots worldwide. A 6-axis robot arm can reach, twist, and move similarly to a human arm, enabling it to perform tasks that require careful and skillful work. The design of 6-axis robots allows operation from nearly any angle, making them ideal for industries demanding high flexibility and accuracy. Advances in technology have enabled 6-axis robots to fit into tighter spaces and handle a broader range of jobs than ever before.

6-axis robot arm basics

The design of a 6-axis robot arm copies the way your own arm moves. The base keeps the arm steady and lets it turn. The shoulder and elbow joints help the arm reach up, down, and out. The wrist assembly lets the end-effector twist, bend, and turn. This setup allows the 6-axis robot arm to work in tight spaces and handle complex jobs.

Here is a table showing how each main part helps the 6-axis robot arm move:

| Component | Movement Contribution | Associated Axis/Axes |

|---|---|---|

| Base | Keeps the arm stable and lets it rotate left and right | Axis 1 (Waist) |

| Shoulder Joint | Moves the arm up and down, helping it reach high or low | Axis 2 (Shoulder) |

| Elbow Joint | Bends and straightens the arm, moving the wrist closer or farther | Axis 3 (Elbow) |

| Wrist Assembly | Turns, tilts, and rotates the end-effector for precise control | Axes 4 (Wrist Roll), 5 (Wrist Pitch), 6 (Wrist Yaw) |

| End-effector | Uses all axes to do the task, such as gripping, welding, or painting | Utilizes all axes |

The 6-axis robot arm can reach around obstacles and approach objects from many angles. This makes it very useful for jobs that need careful movement and accuracy.

Six joints

A 6-axis robot arm gets its name from its six joints. Each joint gives the arm a special kind of movement. Together, these joints let the 6-axis robot arm move almost anywhere within its work area.

Each joint in a 6-axis robot arm matches a movement you see in your own arm. The base joint lets the arm turn left and right. The shoulder joint lifts the arm up and down. The elbow joint bends the arm. The wrist joints twist, tilt, and rotate the end-effector. This setup gives the 6-axis robot arm six degrees of freedom, just like a human arm.

A 6-axis robot arm can reach almost any point in its work area. It can extend, retract, and rotate to get around obstacles. You can use a 6-axis robot arm to pick up objects, weld, paint, or assemble parts, even in tight spaces. The flexibility and dexterity of a 6-axis robot arm make it a top choice for many industries.

6-axis robots advantages

Flexibility

You can see how flexible 6-axis robots are right away. They move in almost any direction you need. The six joints help the robot arm reach around things and twist. It can work in small or crowded spaces. This means you can use 6-axis robots for many jobs, like welding or putting things together. SCARA robots work best in open, flat places. But 6-axis robots do well in busy or tricky spots. Their six degrees of freedom help them learn new jobs fast. You can program a 6-axis robot to change tasks easily. This makes your work faster and more efficient. In factories, hospitals, and even space, 6-axis robots work where other robots cannot.

- Six-axis robots reach around things and do hard tasks.

- SCARA robots cannot move as much, but 6-axis robots can do more.

- Good software lets you program 6-axis robots for many jobs.

Precision

6-axis robots are very precise. You can trust them to put parts in the right place. Many 6-axis robots can repeat a task with almost no mistake. Some can be as exact as ±0.02 mm. Good sensors and smart controls help them stay accurate, even when moving fast. In high-tech jobs, being precise is very important. 6-axis robots use special sensors and smart programs to make sure every move is right. This helps stop mistakes and makes better products.

- Six-axis robots use smart sensors to handle things gently.

- Checking and programming often keeps them accurate.

- High precision means fewer mistakes and better work.

Productivity

6-axis robots help companies get more done. They can make things faster, make fewer mistakes, and save money on workers. These robots work quickly and never get tired, so you get steady results all day. Companies have seen big improvements after using 6-axis robots. For example, a car factory made cars 30% faster and had 25% fewer mistakes. In electronics, 6-axis robots helped make 20% more products. Their small size lets you put them in tight spots, so you do not have to change your whole workspace. This makes it easier and cheaper to use robots.

Six axis robot uses

Manufacturing

6-axis robots are common in today’s factories. They do jobs that need careful movement and accuracy. You can use them for picking parts, moving materials, stacking, sorting, putting things together, packing, and painting. Many businesses like car makers, airplane builders, metal shops, and companies that make things for people use 6-axis robots. These robots can reach hard places and do tricky work. You can put a 6-axis robot arm on the floor, wall, or even the ceiling. This helps you fit the robot into your workspace. It is easy to change what the robot does if you make new things or change your process.

| Manufacturing Process | Why Use 6-Axis Robots? |

|---|---|

| Part Picking and Handling | High dexterity and complex movements |

| Painting | Precise, intricate movements for complex surfaces |

| Material Removal | Strength, reach, and accuracy |

| Assembly | Flexible motion for complex assembly tasks |

| Welding | Dexterity and ability to reach tough angles |

Electronics

6-axis robots work in electronics factories. They put together circuit boards, place small parts, and solder pieces. These robots move very carefully, which is important for electronics. They fit in small spaces and can move around things in the way. Their small size lets you do more work without making the area crowded. You can set them up in different ways to fit your needs. Using 6-axis robots helps you make more products and keeps the quality high, even if you change what you make a lot.

- Circuit board assembly

- Component placement

- Soldering

- Quality inspection

Food and logistics

6-axis robots help in food factories and warehouses. They make work faster and safer. In food plants, they pack, stack, and check the quality of food. Their smooth surfaces are easy to clean and help keep food safe. In warehouses, 6-axis robots pick, pack, sort, and stack goods. You can use them to keep track of items and make fewer mistakes. These robots work well in small areas and can handle many types of products.

Note: 6-axis robots in food factories use special parts and designs to stay clean and safe.

Medical

6-axis robots help in hospitals and labs. They are used for surgery, lab work, and making medical tools. These robots help doctors do careful work, like prostate surgery and hip replacements. They move smoothly and help doctors be more exact. In labs, 6-axis robots handle samples and do the same job over and over. Their careful movement and flexibility make medical work safer and better.

| Robot/System | Medical Task | Role and Benefit |

|---|---|---|

| PROBOT | Prostate surgery | High precision, less surgeon fatigue |

| ROBODOC | Hip replacement | Precise bone carving, better implant fit |

| AESOP | Laparoscopic camera positioning | Stable video, hands-free operation |

You can count on 6-axis robots to do good work in any field. Their careful movement, flexibility, and ability to work by themselves help you solve hard problems and make your work better.

6-axis robot cost

Price range

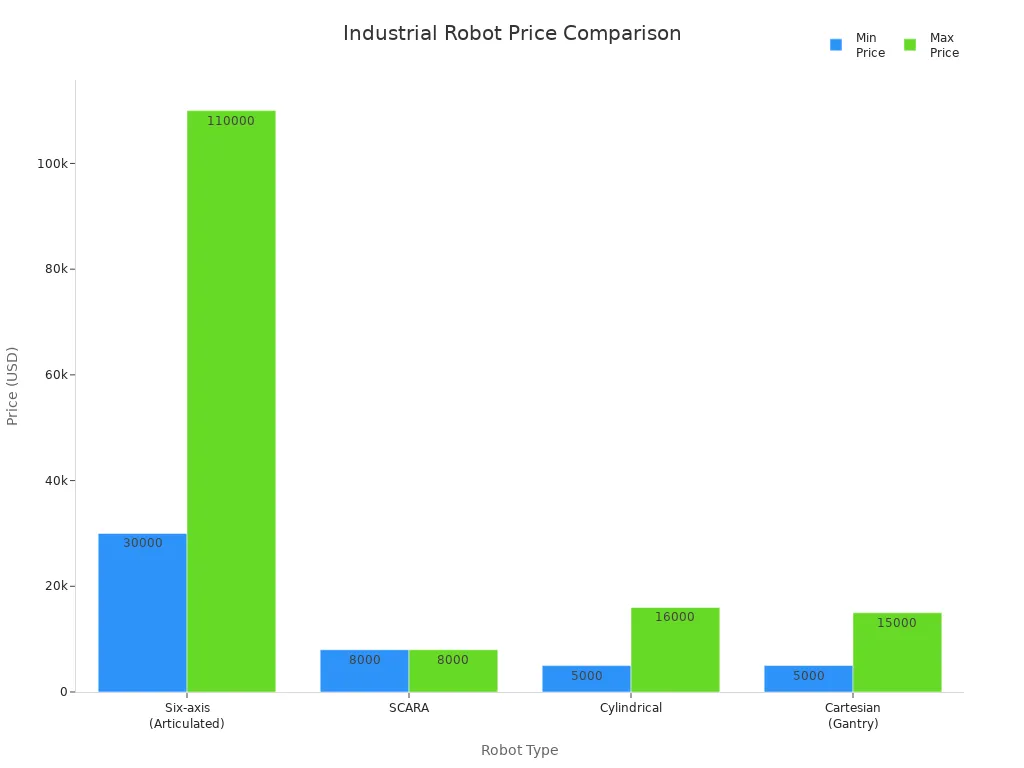

When you look at 6-axis robot prices, you will see a wide range. Entry-level 6-axis robots usually cost between $30,000 and $40,000. Mid-range models can reach up to $50,000. Heavy-duty or advanced 6-axis robots often cost $100,000 or more. You also need to think about extra costs like installation, training, and yearly maintenance. These can add thousands of dollars to your total investment.

| Robot Category | Typical Price Range | Example Model(s) |

|---|---|---|

| Entry-level | $30,000 to $40,000 | Standard Bots RO1 ($37,000) |

| Mid-range | $30,000 to $50,000 | Universal Robots UR10e (~$45,000) |

| Heavy-duty / Advanced | $100,000 or more | FANUC CRX-10iA |

You will find that 6-axis robots cost more than robots with fewer axes. This is because they can move in more ways and do more complex jobs. For example, a 6-axis robot like the UR10e costs about $45,000, while a SCARA robot may cost only $8,000.

Cost factors

Many things affect the price of a 6-axis robot. Here are some important factors:

- Robot type and size: Bigger robots or those with longer reach cost more.

- Payload capacity: Robots that lift heavier items have higher prices.

- Degree of automation: Advanced software and sensors raise the cost.

- Customization: Special tools or programming add to the price.

- Installation and integration: Setting up a 6-axis robot arm can cost $5,000 to $20,000.

- Maintenance and training: Yearly upkeep and staff training can add thousands more.

- Extra features: Vision systems or force sensors make 6-axis robots more expensive but improve performance.

You can choose from many models. Some have folding arms for tight spaces, while others offer high speed or extra precision. When you plan your budget, remember to look at the total cost over the robot’s life, not just the starting price.

A 6-axis robot arm helps you work with more flexibility and accuracy. This makes it easier to use robots in many jobs. 6-axis robots help you do more work and make fewer mistakes. They can also change to do new tasks when needed. Before you buy one, think about what you need the robot to do. You should also look at your budget and how much space you have. If you plan well, you can get the best mix of accuracy, speed, and price.