What is robotic welding? It is a technology that uses robots welding to join metals with exceptional accuracy and speed. In 2025, factories widely employ robotic welding, utilizing advanced Robotic Arms to enhance production efficiency beyond human capabilities. This automation can boost productivity by up to 50% compared to manual welding. Originating in the 1960s, robotic welding has evolved significantly, with robots equipped with Robotic Arms now playing a crucial role in manufacturing processes. EVST Robots stands out as a leading company in welding automation.

| Time Period | Evidence of Growth and Significance |

|---|---|

| 1960s | Robots started being used in U.S. factories |

| 1980s | Car companies began using robotic welding extensively |

| 2005 | Over 120,000 robots worked in North America; about half performed welding |

| Present | Robotic welding accounts for about 20% of all industrial robot jobs |

Key Takeaways

- Robotic welding uses robots to join metals fast and accurately. This helps factories work better and keeps workers safer. Welding robots have important parts like robot arms, sensors, and controllers. These parts help make strong and even welds every time. New technology like AI and cobots make robotic welding smarter and safer. These changes are shaping how factories will work in the future.

What Is Robotic Welding?

Definition and Purpose

What is robotic welding? This is an important question today. Robotic welding uses robots to do welding jobs by themselves. These robots join metal pieces with great speed and accuracy. The main goal is to make more products and better welds by letting robots do the same job over and over. Factories use welding robots for big jobs, so human welders can work on harder or special projects.

Robotic welding began in the 1960s. The first systems were basic, but they changed how factories worked. Over the years, robot welding got better and smarter. Now, welding robots use sensors and smart controls to make strong and even welds. Using robots for welding helps stop mistakes from tired workers and keeps people safe from heat and fumes. Companies like EVST Robots are leaders in welding automation, helping factories get good results every time.

How It Works

The robot welding process uses a robot arm that can be programmed. The robot arm moves a welding torch along a planned path. Engineers or programmers tell the robot what to do. First, the team plans the welding steps and programs the robot. The robot then does these steps again and again with high accuracy.

Sensors help the robot find the right place to weld. Cameras and lasers check where the metal parts are. The robot arm holds the torch steady and moves it at the right speed. The power supply gives energy to the torch, which melts the metal and makes a strong weld. The robot can move in three directions and reach places people cannot.

Modern welding robots use new technology. Some robots use artificial intelligence to change how they weld while working. This keeps the welds strong, even if the metal is not perfect. Factories use robot welding for many types of welding, like arc, spot, and laser welding.

Main Components

Welding robots have many important parts. Each part helps the robot system work well. Here is a table that lists the main parts and what they do:

| Component | Function |

|---|---|

| Robot Arm | Moves the welding torch to the right spot and angle |

| Welding Torch | Heats up and joins the metal pieces |

| Wire Feeder | Feeds welding wire at the right speed |

| Power Supply | Gives the energy needed for welding |

| Controller | Sends instructions to the robot |

| Teach Pendant | Handheld device for programming and control |

| Sensors | Find part position and check weld quality |

| Fixtures & Table | Hold the metal parts steady while welding |

| Safety Systems | Keep workers safe with shields and emergency stops |

Welding robots also use extra tools like wire cleaners and stack lights. Wire cleaners take off spatter from the torch, which helps the tools last longer. Stack lights show if the welding cell is working or needs help.

EVST Robots makes welding robots with smart sensors and controllers. These features help factories get the best results from their robot welding systems. Strong hardware and smart software make robot welding a great choice for factories today.

Robotic Welding Features and Types

Key Features

Robot welding has many helpful features for factories today. One big benefit is precision. Welding robots use special sensors to follow seams and control welding. These sensors help the robot arm put the torch in the right place every time. Some sensors let robots see the work area and make changes as they go. Control systems help manage speed, torch angle, and wire feed. This makes sure each weld is strong and even. Factories need to do regular maintenance and training to keep robots working well. EVST Robots makes welding robots with smart sensors and controls. This gives factories solutions that are reliable and flexible.

Robot Welding Types

Factories use different robot welding types for many jobs. The main types are:

- MIG welding: Uses a wire electrode and shielding gas. It is good for fast, big jobs.

- TIG welding: Uses a tungsten electrode for clean, precise welds.

- Spot welding: Joins metal sheets at small points. It is common in car factories.

- Arc welding: Uses an electric arc to melt and join metals.

- Laser welding: Uses a laser beam for fine, detailed welds.

- Plasma welding: Uses a plasma arc for deep, strong welds.

| Welding Type | Best Use Case | Key Feature |

|---|---|---|

| MIG | High-speed, large batches | Fast, repeatable |

| TIG | Thin metals, clean finish | High precision |

| Spot | Sheet metal, automotive | Quick, strong joints |

| Arc | General fabrication | Versatile, robust |

| Laser | Electronics, medical parts | Fine detail, low heat |

| Plasma | Thick metals, heavy duty | Deep penetration |

Safety and Efficiency

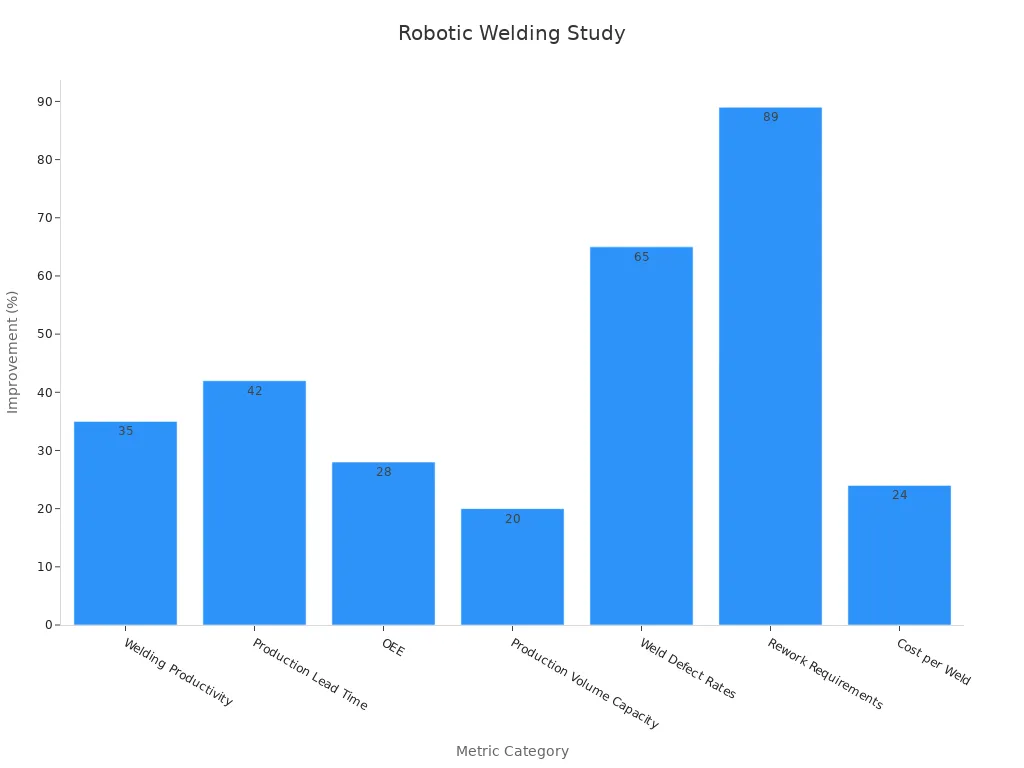

Robot welding makes factories safer and more efficient. Robots do dangerous jobs, so workers stay away from heat and sparks. Sensors in robots can find obstacles and stop the work if needed. This helps prevent accidents. Robot welders also help save materials and energy. This makes production faster and less wasteful. Studies show robot welding can boost productivity by 35% and cut lead times by 42%. EVST Robots makes welding robots that can do many tasks. This helps companies stay safe and get more done.

Applications and Future Trends

Industry Applications

Robot welding is now very important in many fields. In car factories, robots do most of the welding jobs. They work on car bodies and in assembly lines. These robots help make cars strong and safe. They also help build cars faster. Electronics and medical factories use robots for tiny, careful welds. In energy and transport, companies like TYCROP use robots with AI. These robots handle many different parts and help when there are not enough workers. The table below shows how robot welding is growing in different places and jobs:

| Aspect | Details |

|---|---|

| Automotive Growth | $2.26B (2023) to $5.7B (2032) |

| Manufacturing Growth | $0.54B (2023) to $1.34B (2032) |

| Regional Leaders | North America, Europe, Asia-Pacific |

| Key Drivers | Automation, quality, labor shortages |

Innovations for 2025

Robot welding is changing quickly. Cobots can now work safely next to people. These cobots use sensors and cameras to stop accidents. Companies use easy plug-and-play robots and rent robots as a service. New robots use AI to change welding settings while working. This makes welds better. Augmented reality and virtual reality help train workers in safe, digital worlds. Some companies are trying mind-controlled robots, but this is still new. Experts think there will be more digital tools, green machines, and smart checks by 2025.

- Cobots help factories do more work and fill job gaps.

- AI and cloud tools help robots get smarter.

- Easy programming lets anyone teach a robot to weld.

EVST Robots’ Role

EVST Robots is a leader in robot welding. The company checks safety and quality every month. EVST Robots puts smart sensors and controls in all their robots. The company cares about worker safety and quick progress. EVST Robots gives flexible robot welding choices for many jobs. Their focus on safety, training, and new tech helps factories stay ahead. For more details, visit EVST Robots.